Yankee Fork Gold Dredge - Stanley, Idaho

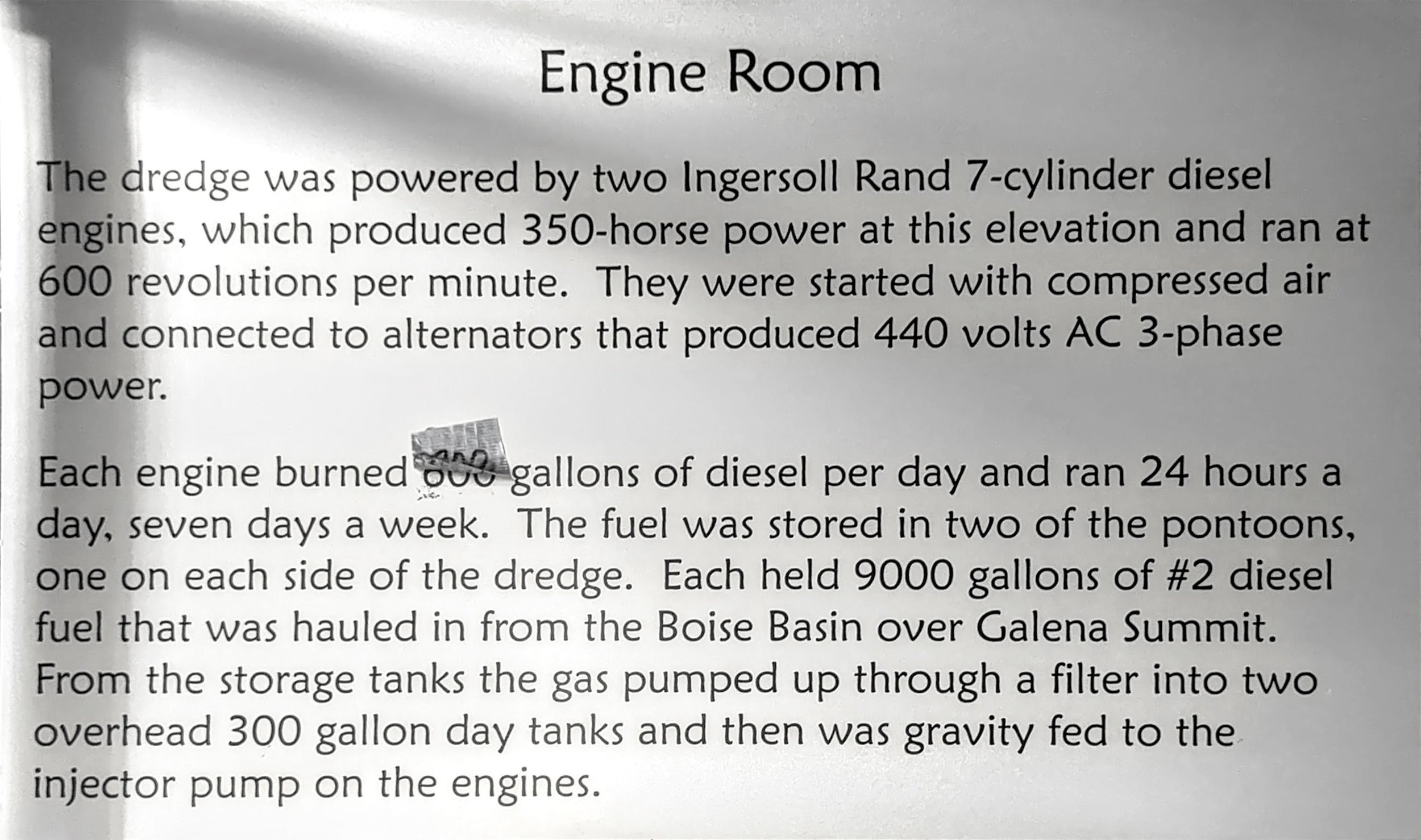

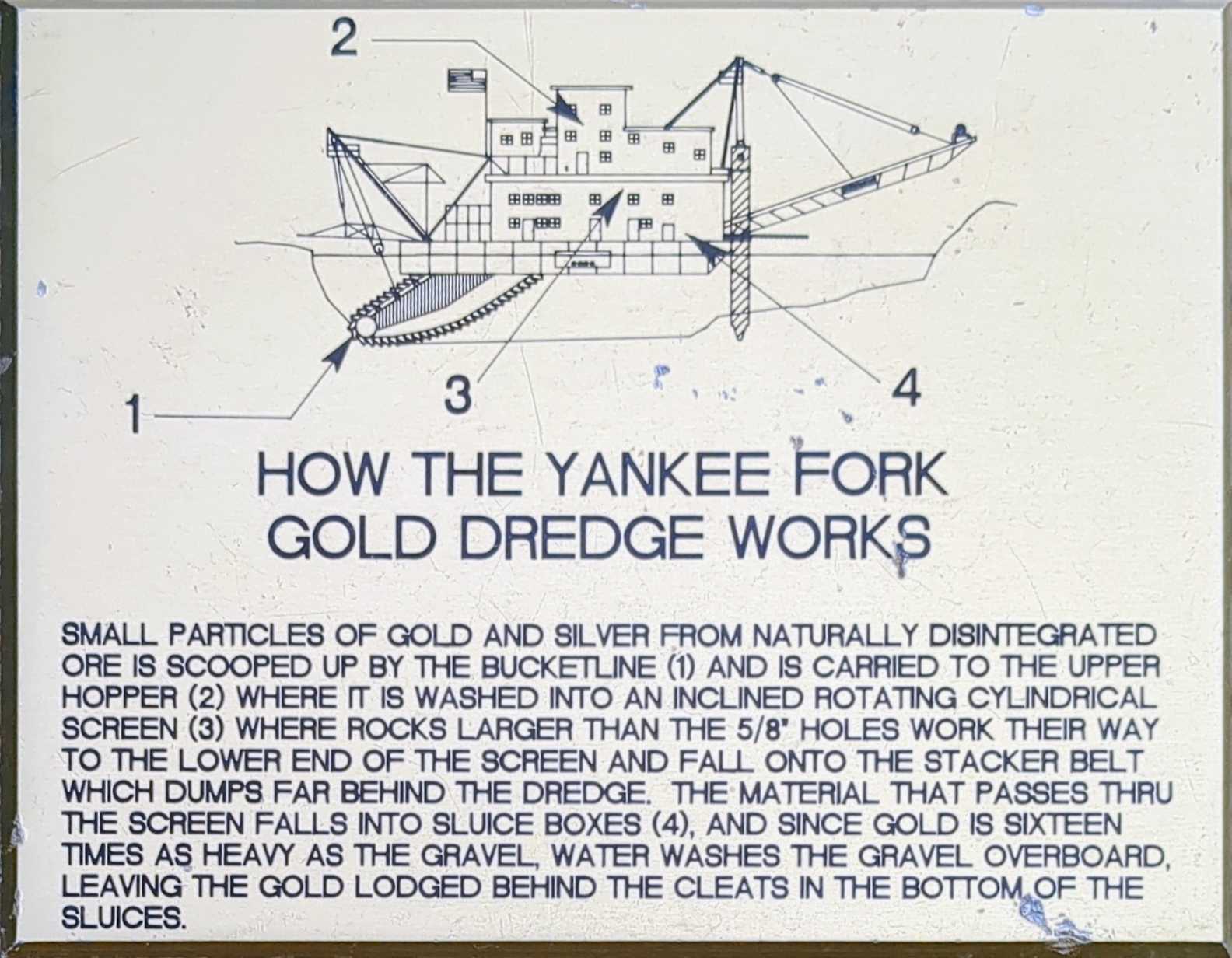

Situated on the Yankee Fork River, the Yankee Fork Gold Dredge is between the historic mining towns of Custer and Bonanza. It's recognized as the largest self-powered dredge in Idaho and stands as a well-preserved testament to early 20th-century gold mining technology. Constructed in 1940 by the Bucyrus-Erie Company for the Snake River Mining Company, the dredge operated until 1952. Measuring 112 feet long, 54 feet wide, and 64 feet high, with a weight of 988 tons, the dredge housed seventy-one 8-cubic-foot buckets, each weighing over a ton. Its operation relied on two 350 HP Ingersoll-Rand diesel engines. The dredge extracted gold from the riverbed using a continuous digging and separation process. The buckets on the rotating chain dug up the gold-bearing gravel, which was washed and screened onboard. A complex system of riffles and mercury traps aided in separating the gold. The Yankee Fork Gold Dredge Association, a volunteer-run organization, plays a vital role in preserving and showcasing the dredge. Visitors can explore the dredge, learn about its history, and view a picture gallery and artifacts.

Hours of Operation

Open Saturday before Memorial Day through Labor Day

Daily from 10 AM to 4:30 PM

Admission (Self-Guided Tours)

Adults – $5

Children 6-12 – $1

Group rates available

Equipment

Sunscreen

Comfortable shoes or sandals

Dress for the weather

Water Bottle

Approach

The Yankee Fork Gold Dredge is north of Stanley, Idaho. From Stanley, head north on ID-75 N toward Clayton. At 13 miles, you’ll come upon Sunbeam Dam/Yankee Fork Historic Display on your right and your turn-off ID-75 on the left. Turn left onto Yankee Fork Rd and follow for 8.5 miles. The dredge will appear on your left, directly off Yankee Fork Rd. To visit Bonanza ghost town before reaching the dredge, from Yankee Fork Rd, turn left onto W Fork Yankee Fork Rd about half a mile before reaching the dredge. There isn’t much to Bonanza besides some campgrounds, a ranger station (44.372347, -114.729641), and a cemetery (44.371872, -114.735126). Beyond the dredge lies Custer, Idaho, a “ghost town” with an active store with souvenirs and some treats. The ghost town portions consist of several original buildings that serve as an outdoor museum of the once-booming gold town. Information signs can be found throughout the town and in some buildings—a great stop after visiting the dredge.

Historical Timeline

1930s: Placer miners see the potential for large-scale dredging in the Yankee Fork.

1939: Silas Mason company invests in the project.

1940: (April 1st - August 24th): Dredge construction.

1940:1942: Initial operation.

1942:1946: Dredge inactive due to World War II.

1947: Snake River Mining Co. sells the dredge.

1949: J.R. Simplot and Fred Baumhoff purchase the dredge.

1950: Dredging operations resume.

1952: Dredging ceases due to exhausted claims.

1966: J.R. Simplot donates the dredge to the U.S. Forest Service.

1979: The Yankee Fork Gold Dredge Association forms, initiated by former employees and their families.

1980: Public tours commence.

Exterior

This behemoth of historic engineering measures 112 feet long, 54 feet wide, and 64 feet tall and weighs just under 1,000 tons. Twenty-five pontoons, measuring 10x10x27 feet each, kept this monster afloat while it processed tons of material daily from the river’s bed. Seventy-one buckets, built in a ladder design, would transfer 7,000 cubic yards of material every day. It could dig up to 37 feet deep and rise to dig at a height of 6 feet above the water line. Each bucket, weighing just over 1 ton empty, would scoop up eight cubic feet of material from the river and transfer it to the top of the ladder, where it would dump the material onto the belt that would move material through the rest of the process. Each bucket would make a round trip on the ladder every two minutes. A system of pullies and cables would move the bucket ladder to where it was needed to collect material.

On the opposite side of the dredge was the stacker. This long arm would take the unused “tailings” (material that remained after extracting the gold) and dump it behind the dredge. The stacker was originally 90 feet long but was quickly upgraded to reach 105 feet by 1941. The tailings were moved along a 42-inch wide rubber belt propelled by a 25HP electric motor. The stacker could be moved from side to side to distribute the material better when ejected from the dredge. As you drive along Yankee Fork Rd, you’ll see these tailings as large mounds of river rocks cover the landscape along the road. Currently, the Forest Service is working to rebuild the natural environment from the damage caused by this mining method.

Interior

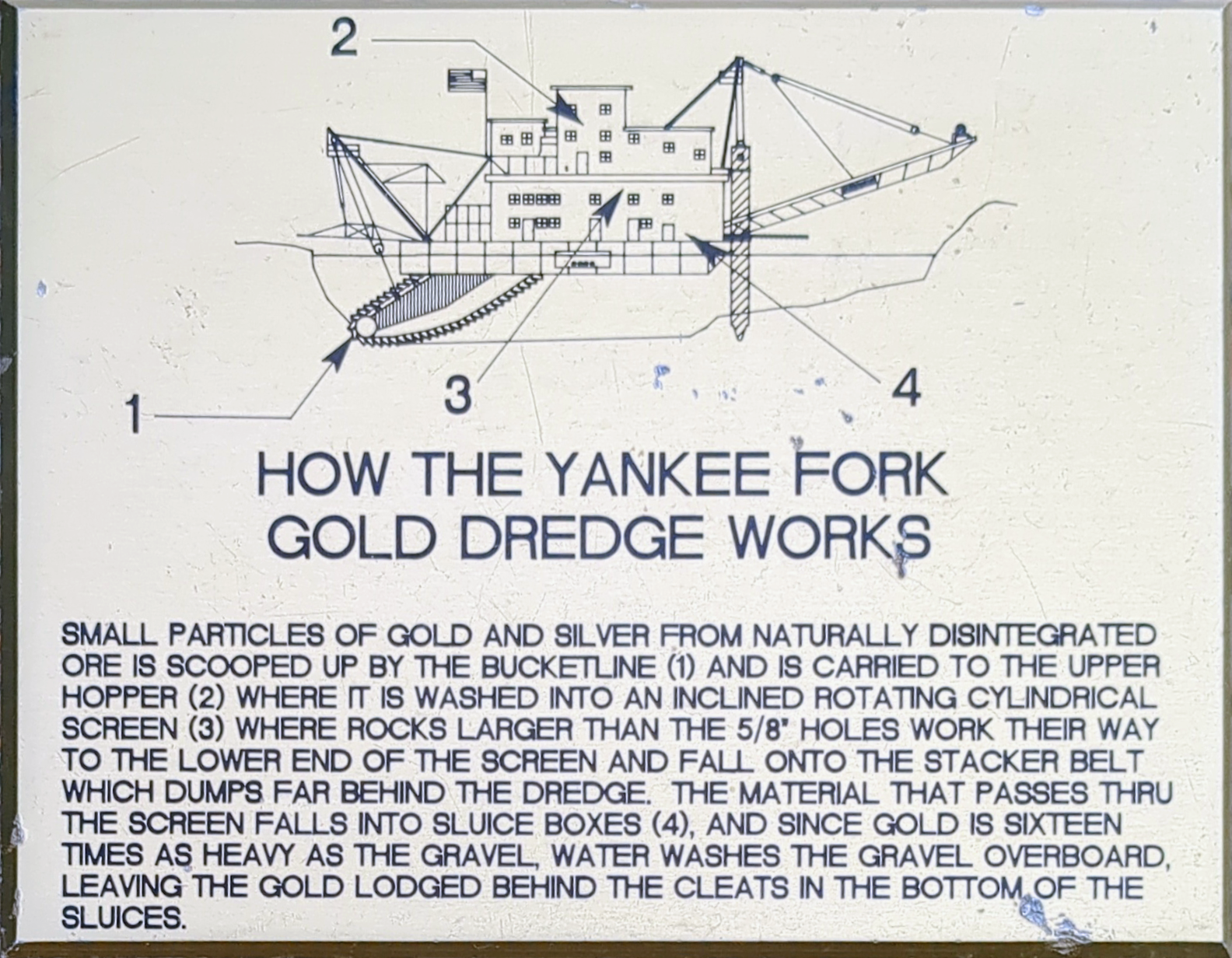

Once the material is dropped from the buckets, it tumbles through giant cylinders with small holes. Imagine a massive washing machine drum. This drum spins slowly while water is pumped over the material. The water would wash the small material through the holes in the trommel plates while the larger material would continue down the trommel towards the stacker. The Yankee Fork dredge had trommel plates with 5/8, 3/8, and 1/4 inch holes that would be changed based on the collected material.

Some material spilled out from the sides of the drum as it was being dumped from the bucket line. This material fell onto the “Save All,” which the dredge master examined. This is where the dredge master would often see what material was being collected by the dredge. If the gold was seen in larger chunks of material, he could order the changing of the trommel plates to maximize the gold collection.

The smaller material that fell through the holes in the trommel ended up in the sluice boxes, where the gold, which is five times heavier than gravel, got trapped in the cleats of the sluices while the other material washed through the system. The “gold man” was the only person allowed into the sluice box area, surrounded by a locked metal cage. The gold man would place a copper plate coated with mercury at the head of each sluice box. The mercury would attract and bond to gold flour, which would help trap it on the rubber plate below the copper one. The gold man maintained the water pressure to ensure it was strong enough to wash away the gravel but not too strong to ensure the gold was retained.

Processing & Shipping the Gold

The dredge shut down every 10 -14 days, and the gold man collected the mercury and gold amalgam into 5-gallon buckets. These buckets were then taken to the retort shack, 4 miles away at the dredge camp. The amalgam would be put into a crucible and placed in the retort furnace, where it would be heated to 700 degrees Fahrenheit. This temperature would turn the liquid mercury into a gas, separating it from the gold. The gaseous mercury would be collected, cooled, and condensed into liquid form. They would recycle this mercury over and over again.

The furnace would now be heated to 1800 degrees Fahrenheit, melting the gold so it could be poured into molds similar to the gold bars we know today. These bars would weigh between 500 and 700 troy ounces. The bars would be stamped with the company stamp, then a federal stamp, and wrapped in paper. The gold man would then do the most secure thing you can imagine, especially given all the security that was in place for the dredge sluice boxes. The gold man would toss the gold bars under the seat of the 1949 Chevy truck, the official company car. Here, the bars would sit until the mail truck was due. The dredge master would then drive the bars 5 miles to Sunbeam Outpost, where they would be mailed parcel post UNINSURED to the mint in Denver.

Specs and Details (For the nerds)

Summary

Yankee Fork Gold Dredge is a piece of incredible historical significance. It is the only Gold Dredge that allows you to examine the entire dredge and all its parts. From start to finish, you will learn all you would ever hope to know about gold dredges and their place in history during the great gold rush of the American West. What’s more, dedicated volunteers are ready to answer any questions. Many of these volunteers had family members working on the dredge or in the camp when it ran. A small gift shop has a few souvenirs and books about the area. We bought a book on ghost towns in Idaho since we were about to visit Custer and Bayhorse ghost towns. We were interested in knowing what other ones might be around Idaho. Overall, this was a fantastic adventure that we loved. Thanks to the volunteers and the forest service, the dredge has been rebuilt into an excellent museum. We were blown away by the details of how the dredge worked and the stories of the people who worked on it. I never imagined finding such a gem in the heart of central Idaho. I highly recommend making this trip and learning about this wild time in our not-so-distant past.

Feel free to visit the Yankee Fork Gold Dredge website for more.